The nut splitters manufactured by Artiman Company are available in seven standard sizes and operate using 700-bar hydraulic pressure. They can safely and spark-free cut nuts ranging from M8 to M48. Larger-sized nut splitters can also be custom-made upon request

To cut the largest nut of each size range, it is recommended to use the next larger size of nut splitter.

For example, to cut an M22 nut with a 32 mm across-flat size, the NC3241 nut splitter should be used.

It is recommended never to use the nut splitter as a wrench for turning or loosening nuts

It is recommended to apply grease to the cutting edge of the nut splitter blade before cutting to reduce the required cutting force.

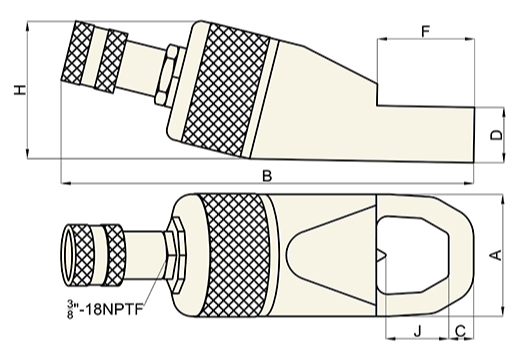

Nut Cutter Model | Bolt Range (mm) | Hexagon Nut Range | Capacity (ton) | Oil Capacity (cm3) | Weight (kg) | Dimension (mm) | Replacement Blade Number | ||||||

A | B | C | D | F | H | J | |||||||

NC 1319 | M8-M12 | 13-19 | 5 | 15 | 1.2 | 40 | 170 | 7 | 19 | 28 | 48 | 21 | NC.B 1319 |

NC 1924 | M12-M16 | 19-24 | 10 | 20 | 2.0 | 54 | 191 | 10 | 26 | 40 | 62 | 25 | NC.B 1924 |

NC 2432 | M16-M22 | 24-32 | 15 | 60 | 3.5 | 64 | 222 | 13 | 29 | 51 | 72 | 33 | NC.B 2432 |

NC 3241 | M22-M27 | 32-41 | 20 | 80 | 5.9 | 75 | 244 | 17 | 36 | 66 | 88 | 43 | NC.B 3241 |

NC 4150 | M27-M33 | 41-50 | 35 | 155 | 10.5 | 94 | 288 | 21 | 45 | 74 | 105 | 54 | NC.B 4150 |

NC 5060 | M33-M39 | 50-60 | 50 | 240 | 15.1 | 106 | 318 | 23 | 54 | 90 | 128 | 60 | NC.B 5060 |

NC 6075 | M39-M48 | 60-75 | 90 | 492 | 39.5 | 156 | 393 | 26 | 72 | 110 | 181 | 80 | NC.B 6075 |

Hydraulic Nut Splitter

A Hydraulic Nut Splitter is a powerful tool whose force is generated by a 700-bar hydraulic pump. It is used for cutting and removing nuts safely through a cold, spark-free process.

Sometimes, nuts in industrial equipment become rusted, or in certain cases—especially in the oil, gas, and petrochemical industries—nuts are intentionally locked in place during production using tools like a bolt tensioner or a hydraulic wrench to prevent loosening. In such situations, it is impossible to remove them using normal methods or the mentioned tools, and using a strong and suitable nut splitter can be very helpful.

The Artiman hydraulic nut splitters, produced in seven standard sizes as shown in the table above and widely used in the industry, are proudly manufactured by Artiman, drawing inspiration from leading brands. Enerpac It manufactures domestically and supplies its products, and has earned the trust of its customers in the industry.

To operate hydraulic nut splitters, a 700-bar manual hydraulic pump (1-ton) together with a hose, gauge, and gauge stand—also manufactured by Artiman—is required.

Important recommendations:

It is recommended never to use the nut splitter as a wrench to turn the nut.

It is recommended to apply grease to the cutting edge of the nut splitter blade to reduce cutting force.

It is recommended to carefully read and understand the user manual of the nut splitter before use.

Artiman hydraulic nut splitters are supplied in high-quality metal boxes, securely packaged, and come with a spare blade and safety hook.

Features of Artiman Nut Splitters:

- Rust and corrosion resistant

- Lightweight

- Comes with a one-year product warranty

- 60 cuts warranty with a maximum hardness of 40HRC for cutting blades

- Availability and after-sales service due to domestic production

- Competitive pricing compared to Enerpac and other foreign brands

Specifications

| Size | NC1319 (M8-M12), NC1924 (M12-M16), NC2432 (M16-M22), NC3241 (M22-M27), NC4150 (M33-M39), NC5060 (M39-M48), NC6075 (M39-M48) |

)?unique=cbc3726)

)?unique=cbc3726)