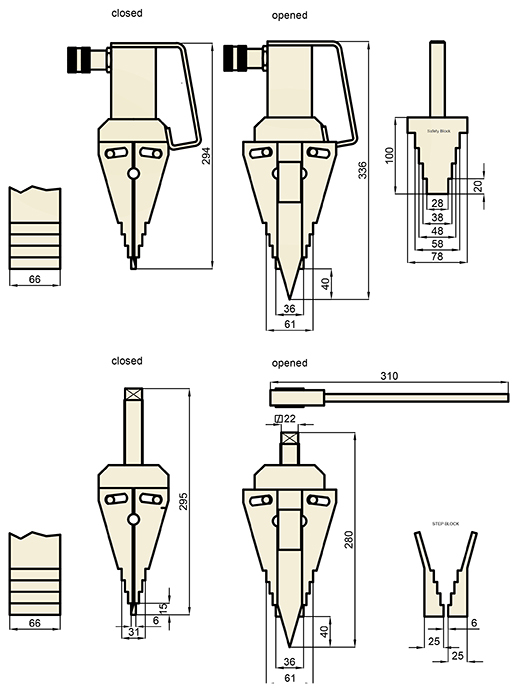

The wedge-type flange spreaders manufactured by Artiman are produced in two models: a 14-ton hydraulic type and an 8-ton mechanical type. For optimal performance, it is recommended to use three units simultaneously, positioned at 120-degree intervals around the flange.

| Oil Capacity (cm3) | Spreader Type | Maximum Spread (mm) | Tip Clearance (mm) | Maximum Spreading Force (ton) | Model |

| 78 | Hydraulic | 80 | 6 | 14 | SW-14H |

| - | Mechanical | 80 | 6 | 8 | SW-8M |

The wedge-type flange spreader

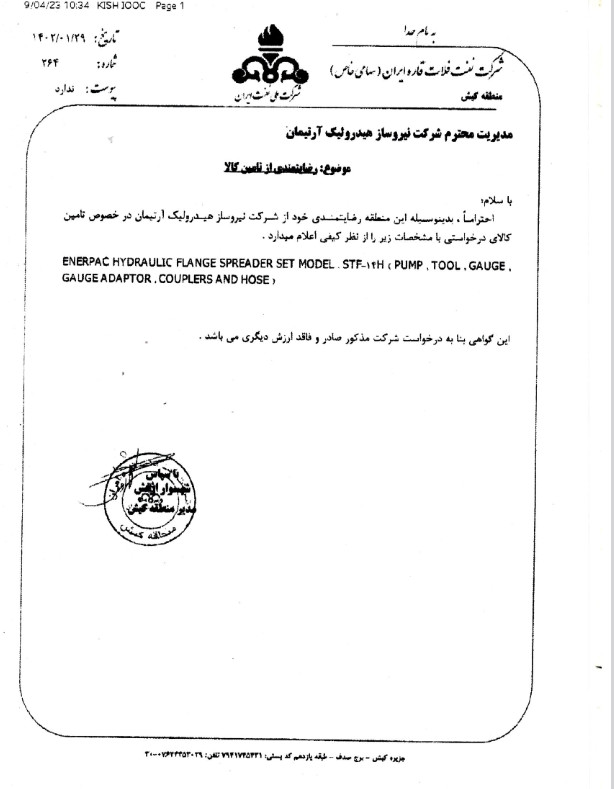

To separate flanges for maintenance or gasket (seal) replacement, a significant amount of force is required. Performing this task with basic tools is timeconsuming and difficult. For this reason, Artiman has designed and manufactured hydraulic wedge-type flange spreaders (Wedge Type Flange Spreader) inspired by Enerpac models. They are available in two versions: the manual wedge-type SW-8M with a capacity of 8 tons, and the hydraulic wedge-type SW-14H with a capacity of 14 tons, produced and supplied according to the specifications shown in the table above.

The SW-8M tool does not require any additional auxiliary equipment for operation

To operate the SW-14H flange spreader, one manual hydraulic pump (1 ton, 700 bar) is required, along with a hose, pressure gauge, and gauge stand — all of which are also manufactured by Artiman Company.

The flange spreaders manufactured by Artiman Company are supplied in a metal case, complete with one step block, one safety block, and one safety hook. To use this tool, a minimum gap of 6 mm between the two flanges is required.

It is recommended to use two flange spreaders simultaneously to extend the tool’s service life and prevent damage to the flange body.

Specifications

| Model | SW-14H, SW-8M |

?unique=34a7c4c)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=34a7c4c)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)

?unique=64b79b0)